斯图加特国际工业胶粘技术展览会(BONDexpo)是德国及欧洲最专业的工业粘接技术贸易展览会,是推进工业粘接技术发展的博览会议,是由P. E. Schall GmbH & Co. KG组织主办,从2007年开始举办,每年一届,与国际安装及使用技术专业展览会-Motek展在德国斯图加特国际展览中心同时举行,吸引更多的专业观众参与。

BONDexpo正变得越来越重要,因此,特别是在事实的事项涉及的紧固件和新材料加入光已经代表了真正的粘接技术的挑战,并将继续这样做,将来也是如此。毕竟,轻质结构不仅是汽车的问题,而是设备和装置,以及一般应用的需要。未来的材料和材料组合,以及混合解决方案,将提供简化和资源潜力,只能通过采取新的粘合剂的使用优势。第四届BONDexpo将调解的国家的最先进的和当前的诀窍之间研发,实际使用和材料的应用。

展会数据:BonDexpo 2012举行第六次参展企业稳步增长达122家;BONDexpo于2011年是第五次举行,共106家企业参展。2009年展会回顾,有1100多家参展商,来自超过21个国家的观展者,总展览面积37,500平方英尺,展会平台是制造商和供应商在粘接,绝缘,发泡,密封和封装材料,以及应用设备等联系的最佳平台,并处理在各自的应用,正变得越来越密切的关系。2010年展有100家参展商,展出面积达37,50平米,不仅推动粘合技术的发展,而且,是粘接,绝缘,发泡,密封和封装材料,以及应用设备的制造商和供应商交流的盛会,并在各自的应用技术处理范围内,正变得越来越密切相关了。

Bondexpo是全球第一大用户会议场所,通过粘合,成型,密封和发泡,通过连接/粘合的工艺链清晰一致地提供了详细的系统解决方案,用于在最广泛的材料的接合和粘合领域的当前和将来的挑战。在资源节约方面的新要求以及通过材料混合/混合设计实现轻量化结构或微系统技术应用的小型化方面的新要求也是至关重要的。粘合技术供应商找到了从全球化生产世界向专业人士介绍的理想环境。

Bondexpo与Motek(国际组装,处理技术和自动化展览会)并行运行。展会集团是一个令人印象深刻的证明,需要考虑箱外,以便能够提供生产和组装技术的工艺链的完整表示,包括通过胶合的基本粘合和连接技术。

展品范围(Show Products):

1、胶粘和密封剂;

2、有机硅产品;

3、透明有机硅凝胶粘接,绝缘,发泡,密封和封装材料等。

展会报告(Show Reports):

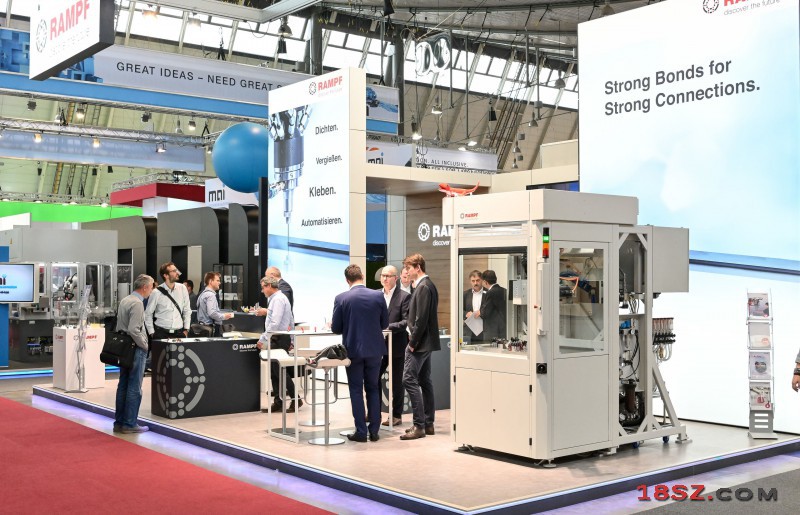

The 42nd Motek international trade fair for automation in production and assembly, together with the 17th Bondexpo international trade fair for bonding technology, have come to a successful conclusion. 409 exhibitors from 19 countries presented new systems and solutions for production automation during the 4-day event. The autumn highlight was accompanied by an attractive, world-class supporting programme.

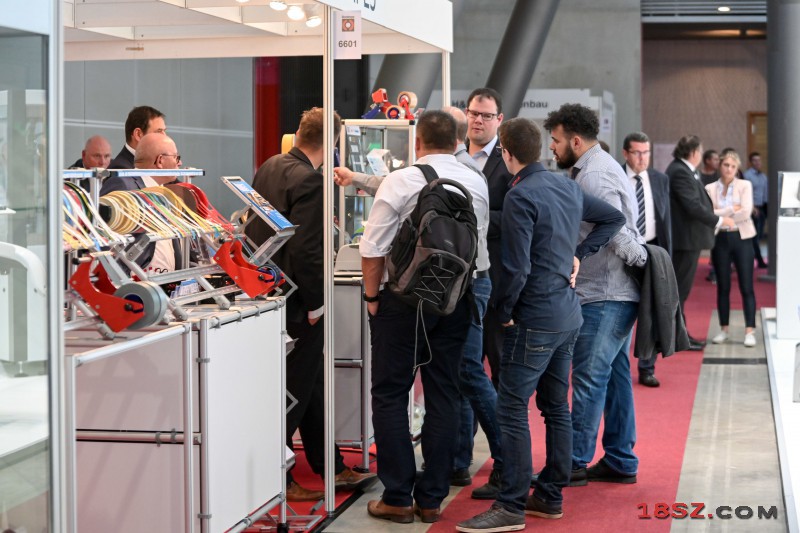

Satisfied faces and lots of positive statements marked the end of the last day of the traditional Motek/Bondexpo trade fair duo in Stuttgart. 409 exhibitors from 19 countries – 26% of whom came from outside of Germany – presented their forward-looking innovations and welcomed 18,948 expert visitors to Stuttgart from the 8th through the 11th of October, 2024. They came with explicit objectives: reduced unit costs, increased productivity, minimised consumption, optimised performance. “These goals are driving new developments,” observes project manager Rainer Bachert. “The trade fair’s main topics were characterised by keywords such as efficiency, competitiveness and sustainability,” says Bachert. “Motek 2024 demonstrated again and again that production is dependent on AI-based processes in a wide variety of areas. Artificial intelligence supports processes and the work force, and is becoming firmly established in manufacturing companies.”

Clear-Cut Thematic Profile, Satisfied Exhibitors

The Motek/Bondexpo trade fair duo is the perfect place for the industry sector to present the entire value added chain for industrial manufacturing. It’s recognised as an ideal business platform because it supports the modern design of manufacturing processes for all parties involved – pragmatically and with a practical approach. Low-cost as well as high-end automation solutions are covered. The range of topics is clearly geared towards industrial manufacturing processes – from raw materials and component handling, as well as sorting and feeding, right on up to assembly, screwing, joining and labelling, and finally discharge and packaging. once again this year, expert visitors experienced various types of feed systems, robot-based handling applications, inline inspection systems including image processing, transfer systems and autonomous logistics, as well as packaging technology. “only Motek offers such a user-oriented format,” emphasised Dr. Ing. Christian Löchte, CEO at FORMHAND Automation GmbH in Braunschweig, Germany. Having originally participated at the trade fair as a startup, the company is now a traditional exhibitor at Motek where it presents flexible gripper pads for gripping, clamping and holding workpieces and products – ranging from car body parts to tomatoes. “We’re in the right place here at Motek, because the trade fair concept is clearly user-oriented and this aligns with our target group,” says Löchte.

Personal Exchange, Matching Target Group

Optimum datamanagement solutions GmbH has also been exhibiting at Motek for many years with its “Clever Klaus”. The camera-based work assistance system, which has received various awards, guides employees step by step at manual workstations, at the same time ensuring that no mistakes are made. “This is a classic Motek topic,” observed managing director Wolfgang Mahanty who, together with his team, has been cultivating personal contact with the relevant target group at the trade fair for years.

Participation at the trade fair was also a forward-looking experience for Robin Geiselbrecht, EU sales engineer at VKS Ltd. (Visual Knowledge Share). The young Canadian enterprise offers browser-based software that helps production companies provide employees with digital instructions and capture live production data. The goal is continuous improvement of the production process – a classic Motek topic. “We’ve been operating in Europe for twelve years and are exhibiting at Motek this year for the second time. The Stuttgart region is home to a significant number of the industrial companies we want to approach. The topics covered by Motek are in line with our target group, as discussions at our booth have shown. We’ll be back again next year.”

Focus on Digitalisation, Software and AI

The two adjacent booths operated by Bott and Assemblio also attracted large crowds with their focus on the integration of software solutions into manual assembly processes. Together, the two companies organised their own supplementary programme with practice-oriented presentations, workshops and podium discussions. The software solution for efficient assembly planning and automated preparation of assembly instructions developed by Assemblio GmbH attracted many interested expert visitors to the booth, who wanted to learn more about process optimisation in production and assembly, as well as the practical implementation of AI and inter-system networking.

Robert Patric Fabian, CEO of Einzelkind Software GmbH in Karlsruhe, was also extremely satisfied with the large number of interesting meetings. The young company develops customised cloud software solutions for B2B customers. “We met up with the relevant target group who are interested in our digitalisation solutions here at Motek.” Startup Inbolt from France also attracted a great deal of attention with its presentation of GuideNOW – a real-time robot guidance solution based on 3D vision and AI. It consists of a 3D camera mounted to the robot, real-time AI for workpiece localisation and a web application for training the AI algorithms on any CAD model or 3D scan.

Motek/Bondexpo Leading the Way: from Components to Systems

Over the decades since its inception, the trade fair has risen from the component level to the overall process chain. “Time and again we hear that Motek is simply indispensable,” reports project manager Bachert. “It presents viable solutions. once again this year, it demonstrated that it has never been easier to get started in automation. And it offered lots of information on AI,” says Bachert. AI was a key topic at the forum presentations, which were very well received. “We’re very pleased with the successful conclusion of this autumn event,” says Bettina Schall, managing director of trade fair promoters P. E. Schall. “This proven trade fair was once again the perfect platform for bringing together suppliers and users from the factory automation industry in a personal, practice-oriented manner. In many ways, Motek/Bondexpo has once again been able to generate forward-looking impetus and make a valuable contribution to helping manufacturing companies position themselves for the future. I would like to express my sincere thanks to all exhibitors, expert visitors and interested guests for the lively exchange in a constructive working atmosphere! We’ll carry this outstanding, inspiring atmosphere over from 2024 to next year’s event – the 43rd Motek and the 18th Bondexpo from the 7th through the 9th of October, 2025.